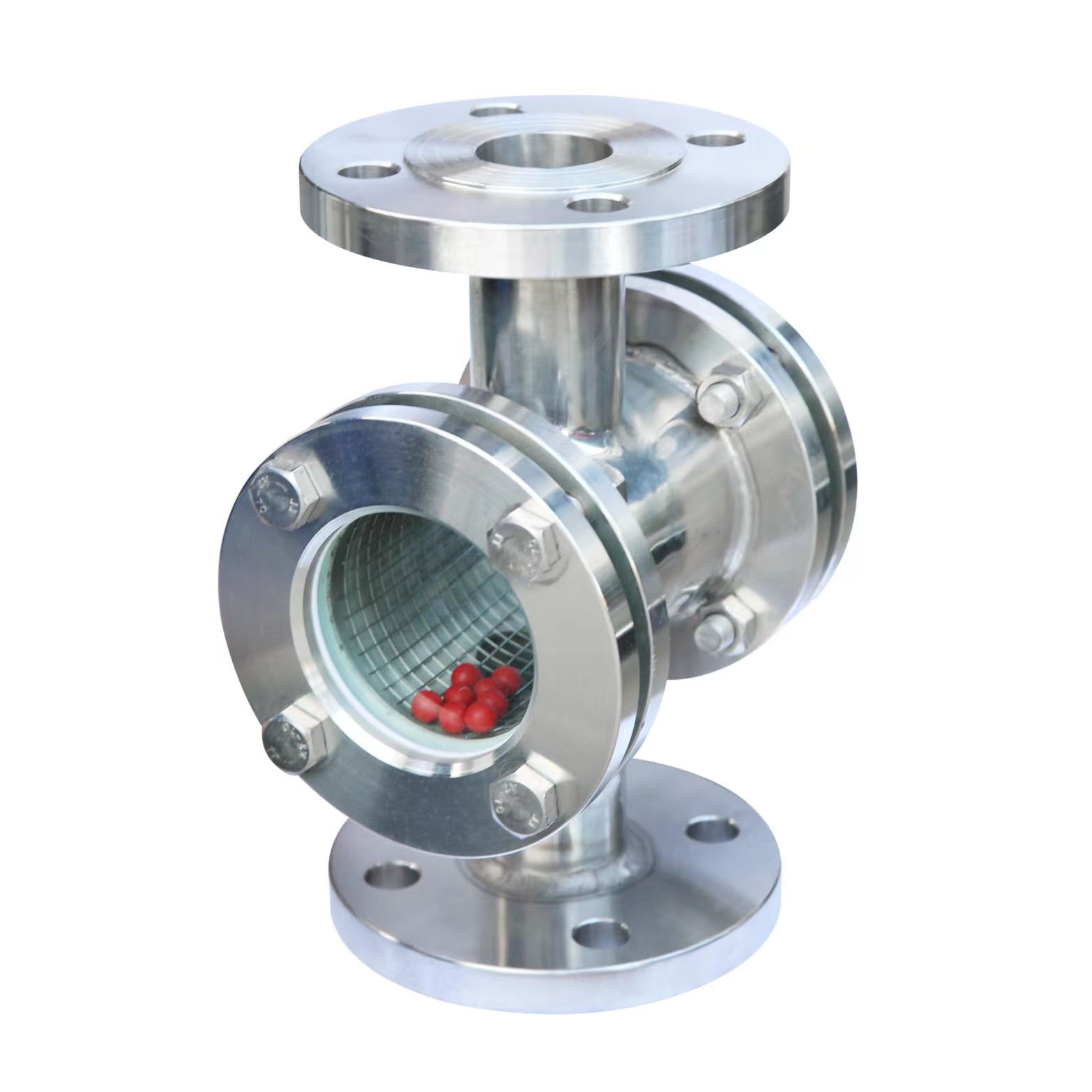

The important role of Sight Glass Flow Indicator in food processing plants

2024-10-01

What Are the Key Features of Coriolis Mass Flow Meters

2024-11-15In the field of flow measurement, the vortex flow meter stands out as a remarkable device, offering a host of impressive features that make it an invaluable tool in various industries.

One of the most significant advantages of the vortex flow meter is its wide measurement range. It is capable of accurately measuring the flow of not only one but multiple mediums, including steam, gas, and liquid. This versatility makes it applicable in a diverse array of applications, from industrial processes that involve the handling of different fluids to energy production where the measurement of steam and gas is crucial. Whether it’s in a chemical plant monitoring the flow of liquid chemicals or a power station measuring the flow of steam for power generation, the vortex flow meter can handle it all with ease.

Accuracy is another hallmark of the vortex flow meter. It provides precise measurements, ensuring that the data obtained is reliable and can be used for critical decisions. In processes where even small deviations in flow can have significant implications, such as in pharmaceutical manufacturing where precise dosing of liquids is essential, the high accuracy of the vortex flow meter is a major advantage. It helps to maintain the quality and consistency of the production process, reducing waste and improving overall efficiency.

The vortex flow meter also features small pressure loss. This means that it has a minimal impact on the fluid flow system it is installed in, ensuring that the energy required to move the fluid is not significantly increased. In large-scale industrial operations where energy costs are a concern, this can result in significant savings over time. Additionally, the low-pressure loss helps to maintain the integrity of the system and reduces the risk of damage or malfunction due to excessive pressure drops.

Moreover, the vortex flow meter can provide valuable information beyond just the flow rate. It can measure and provide data on the flow velocity distribution, fluid pressure, temperature, density, and viscosity. This comprehensive set of data allows for a more in-depth understanding of fluid dynamics and can be used for advanced process control and optimization. For example, in a food processing plant, understanding the temperature and viscosity of the liquid being processed along with the flow rate can help in adjusting the processing parameters to ensure the best quality product.