Unveiling the Superiority of Vortex Flow Meter: A Comprehensive Overview

2024-10-16

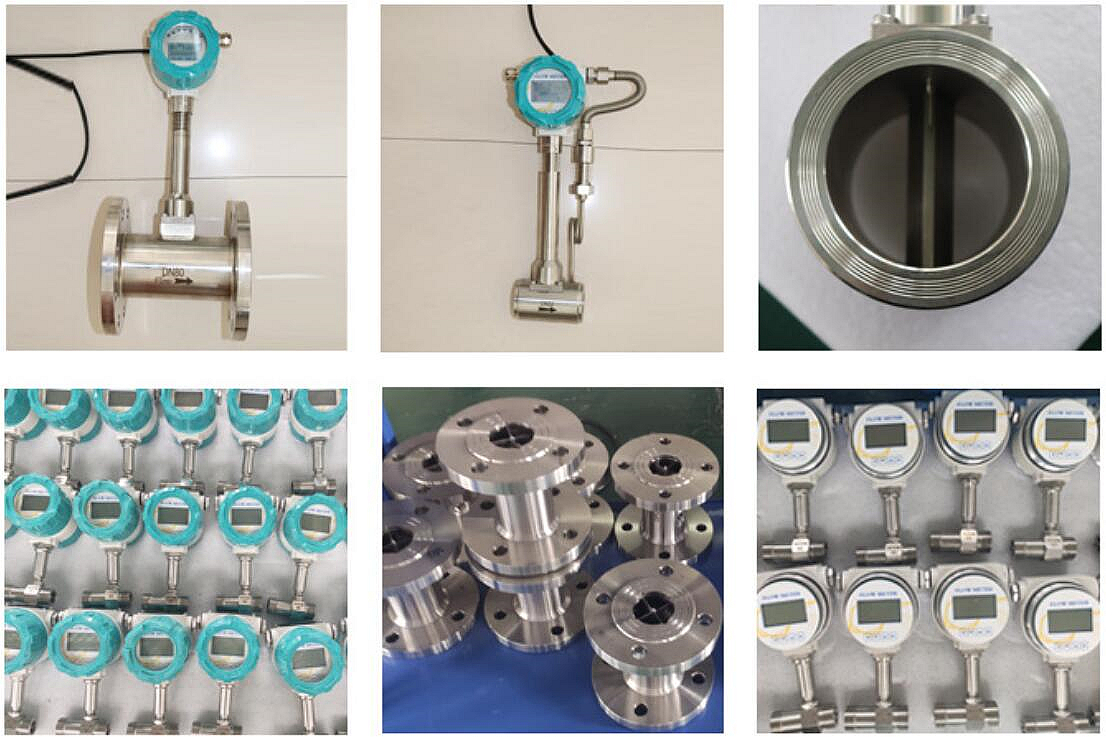

Vortex Flow Meter Customer Use Cases

2025-01-06Coriolis Mass Flow meters stand out due to their unique ability to measure mass flow directly. Unlike other flow meters, they provide precise measurements unaffected by changes in fluid properties. These meters achieve exceptional accuracy, with errors as low as ±0.05%, making them indispensable in industries like oil and gas. Additionally, they offer the advantage of measuring density and temperature simultaneously, enhancing their reliability across various applications. This integrated measurement capability ensures that processes remain efficient and optimized, providing real-time data crucial for maintaining high standards in production and quality control.

Direct Mass Flow Measurement

Coriolis Mass Flow meters excel in providing direct mass flow measurement, a feature that sets them apart from other flow measurement technologies. This capability stems from their unique operating principle, which leverages the Coriolis effect to deliver precise and reliable data.

Principle of Operation

How Coriolis Effect is Utilized

Coriolis Mass Flow meters operate by channeling the fluid through a vibrating tube. As the fluid moves, it experiences Coriolis forces, which cause the tube to deform. This deformation is directly proportional to the mass flow rate of the fluid. By measuring the degree of tube deformation, the meter can accurately determine the mass flow. This method ensures that the measurement remains unaffected by changes in fluid properties, such as viscosity or density.

Benefits of Direct Mass Measurement

The direct measurement of mass flow offers several advantages. It eliminates the need for additional calculations or compensations for fluid properties, resulting in more straightforward and accurate readings. This precision is crucial in applications where even minor discrepancies can lead to significant issues, such as in chemical processing or pharmaceuticals. Furthermore, the ability to measure mass flow directly enhances process efficiency and control, leading to improved product quality and reduced waste.

Applications in Industry

Coriolis Mass Flow meters find extensive use across various industries due to their accuracy and reliability.

Use in Chemical Processing

In chemical processing, precise measurement of mass flow is essential for maintaining product consistency and quality. Coriolis meters provide the accuracy needed to ensure that chemical reactions occur under optimal conditions. Their ability to handle a wide range of fluid types, including corrosive and viscous substances, makes them ideal for this industry.

Use in Oil and Gas

The oil and gas industry relies heavily on accurate flow measurement for both production and distribution processes. Coriolis Mass Flow meters offer the precision required to monitor and control the flow of crude oil, natural gas, and refined products. Their robust design allows them to perform reliably in harsh environments, such as offshore platforms or refineries, where extreme temperatures and pressures are common.

High Accuracy and Reliability

Coriolis Mass Flow meters are renowned for their high accuracy and reliability, making them a preferred choice in various industries. Their ability to provide precise measurements, even in challenging conditions, sets them apart from other flow measurement technologies.

Precision in Measurement

Coriolis Mass Flow meters deliver exceptional precision in measurement, which is crucial for maintaining process efficiency and product quality.

Factors Contributing to Accuracy

Several factors contribute to the high accuracy of Coriolis Mass Flow meters. The direct measurement of mass flow, independent of fluid properties such as density and viscosity, ensures consistent accuracy across diverse operational conditions. The specialized calibration settings and design features further enhance their precision, allowing them to achieve accuracies as high as ±0.05%. This level of accuracy is particularly beneficial in applications requiring stringent control, such as custody transfer of liquids and gases.

Comparison with Other Flow Meters

When compared to other flow meters, Coriolis Mass Flow meters stand out due to their superior accuracy. For instance, while magnetic flow meters offer lower accuracy levels, Coriolis meters achieve 0.1% accuracy over a mass flow range of up to 100:1. This makes them ideal for applications where precise flow measurement is critical. Additionally, unlike thermal meters, which typically have a 1% accuracy range, Coriolis meters provide accurate measurements regardless of fluid type, ensuring reliable performance in various scenarios.

Reliability in Harsh Conditions

Coriolis Mass Flow meters are designed to perform reliably even in harsh environmental conditions, making them suitable for a wide range of industrial applications.

Performance in Extreme Temperatures

The robust design of Coriolis Mass Flow meters allows them to maintain accuracy and functionality in extreme temperatures. Whether in freezing cold or scorching heat, these meters continue to provide reliable data, ensuring uninterrupted process control and optimization. This capability is particularly valuable in industries such as oil and gas, where operations often occur in challenging environments.

Durability in Corrosive Environments

Coriolis Mass Flow meters also exhibit exceptional durability in corrosive environments. Their construction materials and design features enable them to withstand exposure to aggressive chemicals and abrasive substances without compromising performance. This durability reduces maintenance requirements and extends the lifespan of the meters, offering cost-effective solutions for industries dealing with corrosive fluids.

Simultaneous Measurement of Density and Temperature

Integrated Measurement Capabilities

Coriolis Mass Flow meters offer a unique advantage by measuring density and temperature simultaneously. This capability enhances their utility in various industrial applications, providing comprehensive data for process control and optimization.

How Density is Measured

The measurement of density in Coriolis Mass Flow meters relies on the frequency of oscillation of the sensor mounted on the vibrating tubes. As fluid flows through these tubes, its mass influences the oscillation frequency. By analyzing this frequency, the meter accurately determines the fluid’s density. This method ensures precise density measurements, which are crucial for maintaining consistency in processes that require exact fluid properties.

Temperature Compensation Benefits

Temperature measurement plays a vital role in ensuring the accuracy of mass flow and density readings. Coriolis Mass Flow meters incorporate temperature compensation to adjust for any variations caused by temperature changes. This feature guarantees that the measurements remain reliable and accurate, regardless of environmental conditions. The ability to measure temperature alongside mass flow and density provides a holistic view of the fluid’s characteristics, enabling better control and optimization of industrial processes.

Impact on Process Optimization

The simultaneous measurement of mass flow, density, and temperature by Coriolis Mass Flow meters significantly impacts process optimization. This integrated approach offers real-time data that is essential for effective process control and quality enhancement.

Real-time Data for Process Control

Real-time data from Coriolis Mass Flow meters allows operators to monitor and adjust processes promptly. This immediate feedback helps maintain optimal conditions, reducing the risk of errors and inefficiencies. The continuous flow of accurate data supports decision-making, ensuring that processes run smoothly and efficiently.

Enhancing Product Quality

Accurate measurement of mass flow, density, and temperature contributes to improved product quality. By providing detailed insights into the fluid’s properties, Coriolis Mass Flow meters enable manufacturers to fine-tune their processes, ensuring that products meet stringent quality standards. This capability not only enhances the final product but also reduces waste and increases overall production efficiency.

Minimal Maintenance Requirements

Coriolis Mass Flow meters offer significant advantages in terms of maintenance. Their design minimizes the need for frequent upkeep, making them a cost-effective choice for many industries.

Design Features Reducing Maintenance

Coriolis meters incorporate several design features that reduce maintenance requirements.

Self-draining and Self-cleaning Capabilities

These meters often include self-draining and self-cleaning capabilities. This design ensures that fluids do not accumulate within the meter, preventing blockages and reducing the need for manual cleaning. By maintaining a clear flow path, the meter operates efficiently without frequent intervention.

Long-term Stability and Calibration

Coriolis meters provide long-term stability and require minimal recalibration. The robust construction and precise engineering ensure that the meters maintain accuracy over extended periods. This stability reduces the frequency of calibration checks, saving time and resources.

Cost-effectiveness Over Time

While the initial investment in Coriolis meters may be higher, their long-term benefits outweigh the costs.

Reduced Downtime

The reliability of Coriolis meters leads to reduced downtime. Industries experience fewer interruptions due to maintenance or repairs, allowing for continuous operation. This reliability enhances productivity and minimizes losses associated with halted processes.

Lower Operational Costs

Over time, the low maintenance requirements of Coriolis meters translate into lower operational costs. Industries benefit from reduced labor and material expenses related to maintenance activities. The initial investment becomes justified as the meters deliver consistent performance with minimal upkeep, ultimately improving profitability.

Various experts in flow measurement technology highlight that while Coriolis meters may have a higher initial cost, their long-term reliability and accuracy justify this investment. They emphasize that accurate measurements facilitate better decision-making, leading to reduced waste and improved profitability.

Versatility in Fluid Types

Handling of Various Fluids

Coriolis flow meters demonstrate remarkable versatility by accurately measuring a wide array of fluids. This capability makes them indispensable in diverse industrial applications.

Measurement of Liquids and Gases

Coriolis meters excel in measuring both liquids and gases. They utilize the Coriolis effect to determine the mass flow rate, ensuring precise readings regardless of the fluid type. This adaptability allows them to handle fluids with varying densities and viscosities, maintaining accuracy across different conditions. Industries benefit from this flexibility, as it simplifies the measurement process without compromising precision.

Performance with Slurries and Viscous Fluids

In addition to liquids and gases, Coriolis meters effectively measure slurries and viscous fluids. Their design accommodates the challenges posed by these substances, such as abrasiveness and high viscosity. By providing reliable data, Coriolis meters support industries that deal with complex fluid mixtures, ensuring efficient process control and monitoring.

Adaptability to Different Industries

The adaptability of Coriolis flow meters extends to various industries, where they play a crucial role in enhancing operational efficiency and product quality.

Use in Food and Beverage

In the food and beverage industry, precise measurement of ingredients is vital for maintaining product consistency and quality. Coriolis meters offer the accuracy needed to ensure that formulations meet strict standards. Their ability to handle a wide range of fluid types, including those with varying viscosities, makes them ideal for this sector. By providing real-time data, Coriolis meters enable manufacturers to optimize processes and reduce waste.

Use in Pharmaceuticals

The pharmaceutical industry demands stringent control over fluid measurements to ensure product safety and efficacy. Coriolis meters deliver the precision required for accurate dosing and formulation. Their capability to measure mass flow, density, and temperature simultaneously provides comprehensive data for process optimization. This ensures that pharmaceutical products meet regulatory standards and maintain high quality, ultimately benefiting both manufacturers and consumers.

Advanced Digital Communication

Integration with Modern Systems

Coriolis Mass Flow Meters seamlessly integrate with modern systems, enhancing their utility in today’s technologically advanced industrial environments. They support a variety of digital and analog communication protocols, which facilitates easy integration with any control system.

Compatibility with IoT and Industry 4.0

These meters are compatible with the Internet of Things (IoT) and Industry 4.0 standards. This compatibility allows them to connect with smart devices and systems, enabling real-time data exchange and process automation. By integrating with IoT, Coriolis meters contribute to the creation of smart factories where data-driven decisions enhance efficiency and productivity.

Remote Monitoring and Diagnostics

Coriolis Flow Meters offer remote monitoring and diagnostics capabilities. Operators can access meter data from anywhere, allowing for proactive maintenance and troubleshooting. This feature reduces downtime and ensures continuous operation, as potential issues can be identified and addressed before they escalate into significant problems.

Data Analysis and Reporting

The advanced digital communication features of Coriolis Mass Flow Meters extend to data analysis and reporting, providing valuable insights for process optimization.

Real-time Data Access

These meters provide real-time access to critical data, including mass flow rate, density, and temperature. This immediate availability of information allows operators to make timely adjustments to processes, ensuring optimal performance. Real-time data access is crucial for maintaining high standards in production and quality control.

Enhanced Decision-making

The comprehensive data provided by Coriolis Meters enhances decision-making processes. By analyzing the data, operators can identify trends, optimize processes, and improve overall efficiency. The ability to access detailed reports and analytics supports strategic planning and operational improvements, ultimately leading to better outcomes for industries relying on precise flow measurements.

Coriolis Mass Flow Meters stand out due to their exceptional features. They provide direct mass flow measurements, ensuring high accuracy and reliability. These meters remain unaffected by changes in fluid properties, making them ideal for demanding applications. Their versatility allows them to handle various fluids across different industries. Additionally, Coriolis meters require minimal maintenance, offering long-term cost savings. Industries benefit from their precision and efficiency, leading to improved process control and product quality. Considering these advantages, Coriolis Mass Flow Meters are a valuable investment for enhancing operational efficiency and reducing costs.