Differential Pressure Transmitter

2023-01-11

Sight Glass Flow Indicator

2023-01-30vortex flow meter

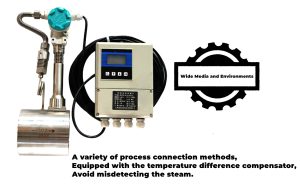

The vortex flow meter is an important instrument for flow measurement and automatic control. It is suitable for flow measurement of gas, liquid, and steam. It is widely used in industries such as petroleum, chemical industry, metallurgy, thermal power, textile, papermaking, electric power, environmental protection, and municipal construction.

Get a quote

Vortex Flow meter, Rotary Flow Meter, Electromagnetic Flow Meter, Turbine Flow Meter, Reduced Bore Vortex Flowmeter, Wide Range Vortex Flowmeter, Compressed Air Flow Meter, Digital Vortex Flowmeter, Flange Clamping Type, Flange Integrated Type, Inserted (Plug-In) Type, Wafer (Clamp-On) Type, Threaded Type, Split Type, Product Category, Flange Clamping Type, Vortex Flow Meter Emerson, Vortex Flow Meter Omega, Temperature And Pressure Integrated Vortex Flowmeter, High-End Vortex Flowmeter, Explosion-Proof Vortex Flowmeter, Plug-In Vortex Flowmeter, High-Temperature Vortex Flowmeter, High-Pressure Vortex Flowmeter, Split Type Vortex Flowmeter, Super Large Caliber Vortex Flowmeter, Thermal Gas Mass Flowmeter, Mass Flowmeter, Precession Vortex Gas Flowmeter, Clamp Type Liquid Turbine Flowmeter, Flange Type Turbine Flowmeter, Thread Type Liquid Turbine Flowmeter, Flange Type Vortex Flowmeter, Clamp Type Vortex Flowmeter, Thermal Mass Flowmeter, Coriolis Mass Flowmeter, Turbine Flowmeter, Variable Area Flowmeter, Metal Tube Rotameter, Sight Glass Flow Indicator

The vortex flow meter is an important instrument for flow measurement and automatic control. It is suitable for flow measurement of gas, liquid, and steam. It is widely used in industries such as petroleum, chemical industry, metallurgy, thermal power, textile, papermaking, electric power, environmental protection, and municipal construction.

How do the Vortex Flow Meters work? The working principle of the vortex flow meter:

If a non-streamlined vortex-generating body (bluff body) is set in the fluid, two rows of regular vortices will be generated alternately from both sides of the vortex-generating body. This kind of vortex is called Karman vortex street. When the fluid flows through the vortex-generating body set in the flow field at a certain flow rate, a pair of alternating and neatly arranged vortex columns (vortex streets) are generated downstream of the column, first on one side of the column, and then Generated on the other side of the cylinder. This theory of vortex generation was first proposed by Karman, named Karman vortex street, and gave the relationship between frequency and flow velocity, and the coefficient was named Strohal number.

Main functions, features, and advantages of our vortex flow meters:

- With a wide measurement range, the flow of steam, gas, and liquid can be measured, with high accuracy, small pressure loss, high reliability, and long-term stability;

- Measurement results and flow velocity distribution, fluid pressure, temperature, density, viscosity, etc.

The rational parameters are irrelevant;

- Simple structure, easy installation, and maintenance, no moving parts, no mechanical wear, no moving parts, high reliability, stable long-term operation;

- Wear-resistant, dirt-resistant, no mechanical maintenance, long service life, safe and explosion-proof,Suitable for harsh environments;

- The sensor measuring probe is packaged with a special process, and the high-temperature resistance can reach 350°C

- The sensor adopts a compensation design to improve the shock resistance of the instrument;

- Using high-tech micro-power consumption, the battery-powered on-site display flowmeter can run continuously for more than five years;

- Electrically isolated current output, good common mode interference suppression ability;

- Brand-new appearance design, the body adopts precision casting technology, beautiful appearance, high-temperature resistance, strong corrosion resistance, good vibration resistance, and zero drift, effectively eliminating the influence of external vibration;

- Surface mount process circuit, compact structure, high reliability, wide measurement range, range ratio up to 10:1, 15:1, 20:1, 30:1

- Small pressure loss, wide dynamic measurement range, low operating cost, stainless steel body, strong corrosion resistance;

- Commonly used signals include pulse or analog signals, stable signals, strong anti-interference ability, pulse output, 4~20mA output or HART communication/Modbus protocol communication, and can be connected with industrial automation systems;

- On-site liquid crystal display, instantaneous flow display, and cumulative total display at the same time;

- Density calculation, temperature and pressure compensation calculation, the online inspection of compensation calculation formula, local key setting, convenient parameter adjustment, and no need for the hand-held communicator.

The Technical parameters of Vortex Flow Meters

- Measuring medium: liquid, general gas, steam;

- Nominal diameter: DN15 ~ DN300 (full pipe type), DN150 ~ DN2000 (plug-in type), DN2000, and above shall be supplied through an agreement confirmed and signed with the customer;

- Medium temperature: -40~100℃ (normal temperature), 100~250℃ (medium temperature), 100~320℃ (high temperature);

- Nominal pressure: 1.6MPa, 2.5MPa, 4.0MPa (>4.0 agreement supply);

- Accuracy: ±1%R, ±1.5%R (full tube), ±1.5%R, ±2.5%R (plug-in type);

- Power supply: +12VDC (three-wire pulse output), +24VDC (three-wire pulse output and two-wire current output) 485 communication; HART protocol, etc., 3.6V lithium battery, dual power supply;

- Body material: 304 (other materials are supplied by agreement);

- Protection level: IP65 (other protection level agreement supply);

- Environmental conditions: temperature -20℃~55℃, relative humidity 5%~90%, atmospheric pressure 86~106kPa;

The caliber selection of the Vortex Flow Meters is very important, and some principles should be followed for selection. The caliber selection: the maximum flow rate of the measured medium, the normal flow rate, minimum flow rate; maximum pressure, common pressure, minimum pressure; maximum temperature, common temperature, minimum temperature; flow measurement. Whether it is in the best working range of the instrument (that is, 1/2~2/3 of the upper limit flow).

The daily maintenance of the Vortex Flow Meters:

The vortex flow meter has no moving parts, so under normal use, it generally does not require frequent maintenance. When the measured medium is dirty or easy to scale, the inner wall of the flowmeter should be cleaned regularly, the vortex generator and detection probe should be well protected during cleaning, and the surface and edges should not be damaged. Non-professionals are not allowed to disassemble the parts at will, so as not to cause damage to the flowmeter. The end cover of the detection amplifier shell should be properly tightened after wiring debugging to ensure its tightness. Do not leave liquid and sundries in the housing during maintenance and inspection.

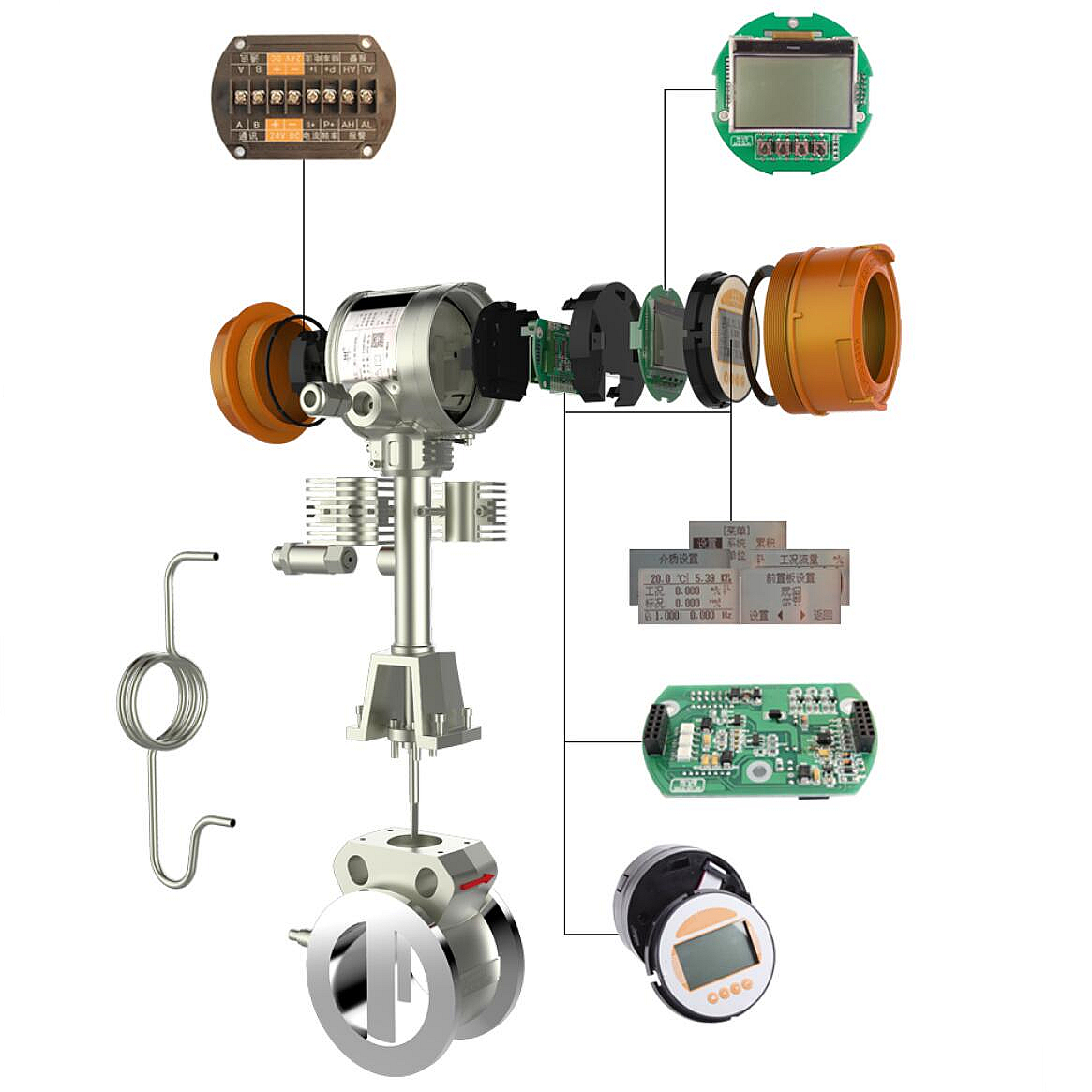

Appearance Characteristics of PESCO vortex flow meter:

Superior Materials include a high-strength aluminum alloy shell and superior stainless steel. PESCO vortex flow meter is stable and reliable, with no maintenance in the whole process.

All parts OF the PESCO vortex flow meter are not loose and maintenance-free during the operation. We have Premium Service Team and Professional Customed Design for Instruments, Gauges & Meters. PESCO vortex flow meter has an excellent circuit design, sensor structure, accurate and reliable measurements, and high sensitivity. There are no moving parts in the measurement process, no mechanical parts damage problems, and no regular maintenance. PESCO vortex flow meter has a stainless steel body, the traditional welding process, combined with high-quality sensors, the overall anti-interference, high-temperature resistance, signal transmission temperature, safe and reliable, and maintenance-free.

We choose the high-quality wiring board, firm wiring, more stable signal transmission, and optional built-in battery power supply, the double power supply is safer and can deal with emergency terminal wiring diagrams.

To get the exact quotations of the vortex flow meters and for more details of Mechanical Properties and Chemical Composition, please contact us freely, you will have instant feedback.

Tel/Fax: +86 10 8599 9168

Whatsapp/Wechat: +86 159 0035 7871

Email: sales@massflowmeter.com, jackywinn@foxmail.com

Related links:

https://www.massflowmeter.com/product/sight-glass-flow-indicator/

https://www.massflowmeter.com/product/differential-pressure-transmitter

https://www.massflowmeter.com/product/coriolis-mass-flowmeter

pipeline ultrasonic flowmeter, glass rotor flowmeter, metal tube rotameter, insertion ultrasonic flowmeter, precession vortex gas flowmeter (stainless steel), gas turbine flowmeter, Portable ultrasonic flowmeter, externally attached ultrasonic flowmeter, electromagnetic flowmeter series, intelligent electromagnetic flowmeter, intelligent plug-in electromagnetic flowmeter, intelligent split-type plug-in electromagnetic flowmeter, sanitary electromagnetic flowmeter, intelligent split-type electromagnetic flowmeter Meter, water meter type electromagnetic flowmeter, electromagnetic heat meter, V cone flowmeter, wedge flowmeter, nozzle flowmeter, integrated orifice flowmeter, integrated porous balance flowmeter, PH balance flowmeter, orifice flowmeter.

Related products

-

Coriolis Mass Flow meters

PESCO provides Cmass Series Coriolis mass flowmeters and Metrological inspection systems. There are professional products and reliable services you can count on, to satisfy your different demands.

Mass Flow Meter, Coriolis Mass Flowmeter, CMASS Mass Flowmeter, liquid mass flow meter, gas mass flow meter, Thermal Mass Flow Meters,Coriolis Mass Flow Meters, Coriolis Liquid Mass Flow Meters Controllers, Coriolis Liquid Mass Flow Meters Sensors, hydrogen gas flow meter, Metrological inspection systems.

Get a quote