How to choose a suitable Coriolis mass flowmeter for oneself

2024-09-23

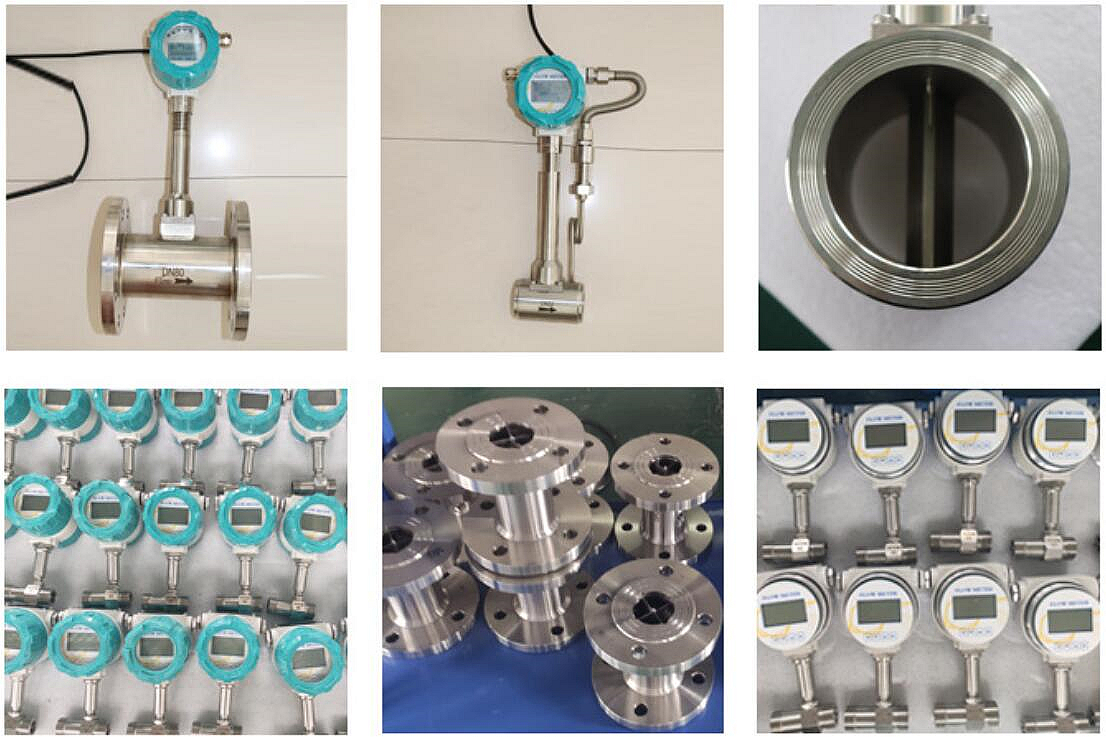

Unveiling the Superiority of Vortex Flow Meter: A Comprehensive Overview

2024-10-16In the food processing industry, every link is related to the quality and safety of products, and precise material flow control is a crucial part of it. The Sight Glass Flow Indicator plays an indispensable role in food processing plants, providing strong guarantees for the efficient operation of the production process and stable product quality.

1. Ensure the accuracy of the production process

Food processing involves precise proportioning and transportation of multiple raw materials. For example, on a beverage production line, water, syrup, juice concentrate, etc. need to be mixed in strict proportions. The Sight Glass Flow Indicator is installed on the conveying pipelines of each raw material, allowing operators to visually observe the flow of each material. By monitoring traffic in real-time, they can promptly detect and adjust any situations that do not match the set traffic, ensuring the accuracy of the mixing ratio. This is crucial for ensuring the taste, flavor, and quality stability of beverages. Similarly, in the process of food processing, the precise addition of various additives and seasonings also relies on accurate observation of the flow indicator on the sight glass, ensuring that each batch of products has consistent quality.

2. Ensure product quality and safety

Prevent cross contamination

In food processing plants, different product production lines may share some piping systems. The flow indicator of the sight glass can help operators clearly distinguish the flow direction and status of materials in the pipeline, avoiding cross contamination between different materials. When switching production products or cleaning pipelines, observing the flow indicator of the sight glass can ensure that the residual materials in the pipeline are thoroughly removed, preventing contamination of the next batch of products by the previous batch of materials, thereby ensuring the quality and safety of food.

Detecting foreign objects and impurities

Sometimes foreign objects or impurities may be mixed into food processing raw materials. If these impurities enter the production process, they may cause damage to equipment, and more seriously, affect product quality, and even pose a threat to consumer health. The transparent design of the sight glass flow indicator allows operators to detect any abnormal objects in the pipeline in a timely manner while monitoring the flow rate. Once foreign objects are found, immediate measures can be taken to stop production, investigate the cause, effectively avoid the production of problematic products, and ensure food safety.

3. Improve production efficiency

Quick troubleshooting

In the process of food processing and production, pipeline blockage or equipment failure may cause poor material flow, thereby affecting production progress. The Sight Glass Flow Indicator can intuitively display abnormal changes in flow rate, such as flow reduction, stagnation, etc., in real-time. Operators can quickly identify the problem based on these signs and take corresponding measures for repair or cleaning in a timely manner. Compared to traditional indirect methods such as relying on pressure sensors to determine pipeline conditions, the direct visualization information provided by the sight glass flow indicator greatly shortens the troubleshooting time, reduces production downtime, and improves overall production efficiency.

Optimize production process

Through long-term observation and analysis of the flow indicator data of the sight glass, food processing plants can optimize their production processes. For example, if it is found that the material flow rate in a certain production process is too high or too low, resulting in low production efficiency or unstable product quality, targeted adjustments can be made to equipment parameters or pipeline layout. In addition, based on the flow demand patterns during the production of different products, reasonable production plans should be arranged to improve equipment utilization and further enhance production efficiency and economic benefits.